Forklifts and pallet trucks are two very different pieces of material handling equipment, but they essentially perform the same task. One of the main differences between the two is initial cost, with a forklift being rather more expensive than a manual or even a powered pallet truck. That’s why it’s important for warehouse owners to be fully-aware of what each machine has to offer their business and Multy Lift will be detailing that information in this article.

What is a forklift used for?

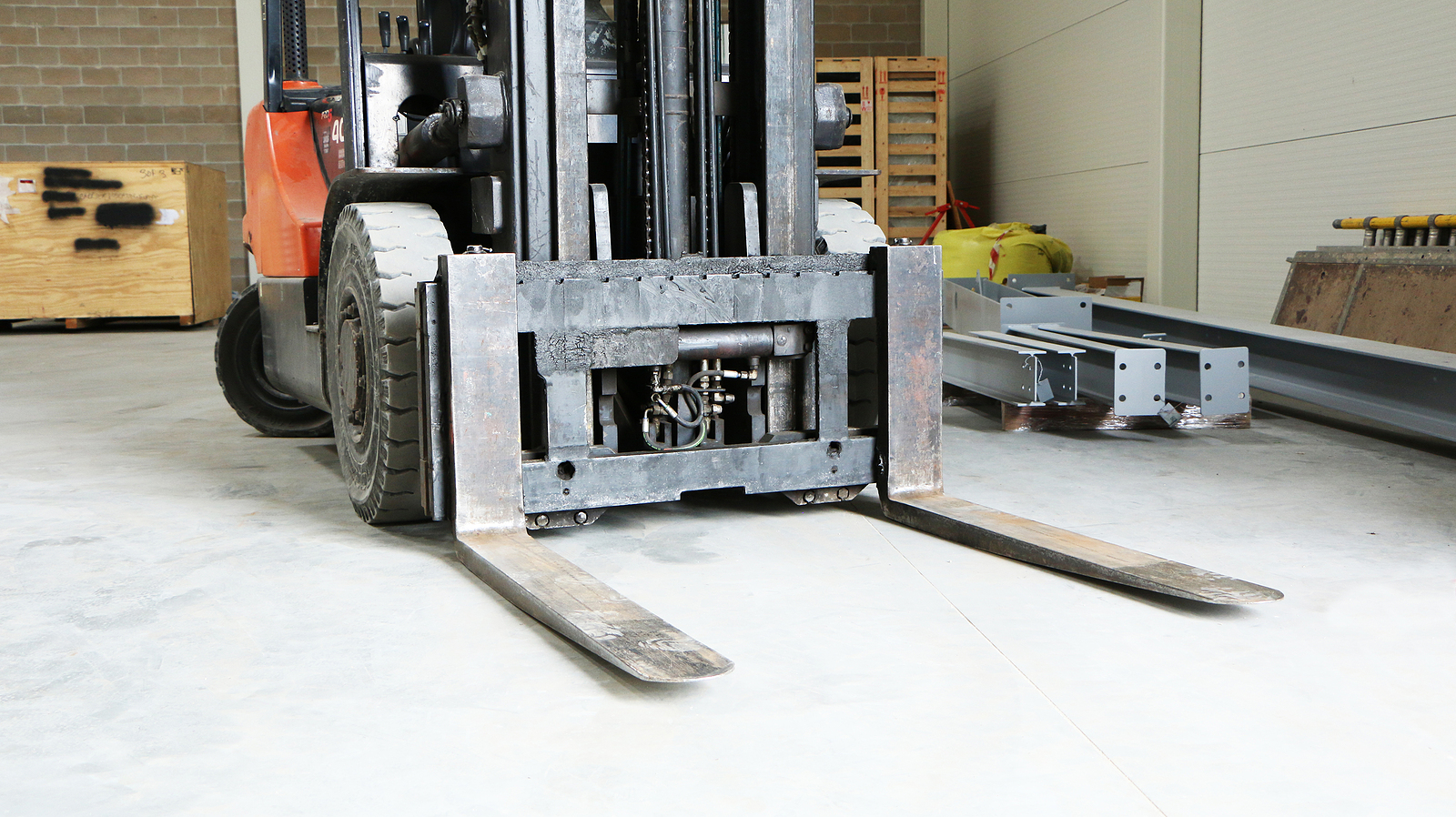

In short, forklifts are used to load, handle, transport and unload large, heavy goods, including pallets or packs. They can manoeuvre stock either vertically or horizontally and come in a variety of different makes, models and fuel types. You’ll be able to choose from electric, diesel or LPG forklifts from a number of the industry’s most renowned manufacturers, including:

- Mitsubishi

- Aisle-Master

- CombiLift

- JCB

- Caterpillar

- Doosan

- Komatsu

- Linde

- Toyota

A forklift is capable of performing a number of different tasks and applications regardless of the industry you work in, whether you opt for new forklifts or used forklifts. A forklift will be able to navigate across loose, uneven or even tough terrain when needed, depending on the model you choose, so you’ll be able to benefit from a forklift even if your premises are spread across two sites. There are also eco-friendly options available for those looking to reduce their carbon footprints.

What are the benefits of a forklift?

There are many different advantages to implementing a forklift, or even a fleet of forklifts, throughout your warehouse and they’re detailed below.

Forklifts are safe, durable and solid pieces of equipment

Forklifts are often rather large, robust machines that are safe to operate at all times, providing your forklift drivers are fully-trained and licenced to maneuver these heavy pieces of warehouse equipment. Responsible operation of a forklift means that everyone remains safe from harm in the workplace, even when working on the warehouse floor.

With advancements in forklift technology, counterweights have been added to ensure the vehicle doesn’t tip over in any direction, although you should ensure that you do not exceed the forklift’s lift or loading capacity.

There are also lights, alarms and other features that make a forklift more safe now than ever before. With the operator in mind, including the addition of a backrest and ergonomically-designed dashboards, your workers will be comfortable at all times when driving a forklift.

Forklifts are easy to manoeuvre, even at maximum load capacity

Forklifts are extremely versatile pieces of equipment, even should they be pushed to their weight limits. Some models are so compact that they can fit into exceptionally small spaces and navigate their way around the narrowest of aisles. Even the smallest of machines will have impressive lifting and handling capabilities, making them one of the best material handling solutions on the market.

There are many different options for warehouse owners to choose from

There are several different types of forklifts available, many of which have already been touched upon. They include electric forklifts, diesel forklifts, LPG forklifts and VNA forklifts. Each type of forklift has its benefits, no matter the fuel type, so you’ll be sure to find an option that effortlessly meets your needs and expectations.

Forklift implementation eliminates the need for manual labour

A reduction in manual labour not only saves time, but it streamlines the entire process whilst simultaneously keeping your employees safe. Fewer workers will be off with injuries and other ailments that have come as a result of using manpower alone to get the job done, thus saving you money, also.

What is a pallet truck used for?

Pallet trucks are smaller and far more simple to operate in comparison to a forklift truck. They’re designed for transporting pallet-sized stock throughout the warehouse, although you might even see them in your local supermarket. Pallet trucks can be manually operated or powered for additional ease.

The worker will stand either on the ground directly behind the machine or on its footings or forks. Subsequently, the operator will slide the forks under the pallet before attempting to lift the load. Then, the pump handle will be used to raise both the forks and the pallet off the ground. Once the pallet truck has been pushed to the desired location, the goods can be unloaded.

What are the benefits of a pallet truck?

There are several benefits associated with the implementation of a pallet truck, whether it’s powered or manually operated. Those advantages include the following:

They have a relatively inexpensive initial cost

In comparison to a forklift, of any fuel type, a pallet truck is rather inexpensive. This means that your initial outlay for effective material handling equipment will be extremely reasonable – a small price to pay for improved efficiency and productivity throughout your warehouse.

Efficiency throughout the warehouse will improve

Pallet trucks eliminate the need for physical manpower which will help to save you time and considerably increase productivity levels. Pallet trucks will also save you money as manual machines won’t need to be electronically charged at your expense. In addition to that, training a worker to operate a pallet truck won’t take long as they’re simple to use.

Workers will be safe when a pallet truck is in operation

Pallet trucks are easy to use and due to the fact that many of the models are manually operated, it leaves little room for risks and hazards to pose themselves to your employees. This means that you’ll have absolute peace of mind that your operators will be kept safe from harm at all times, especially if they have been adequately trained.

Pallet trucks are simple to use

Although some training will be needed in order to ensure the complete safety of everyone involved within the workplace, pallet trucks are exceptionally easy to operate, more so if they’re manually operated as there won’t be any electronics involved. They can also manoeuvre around even the tightest of spaces, somewhere a forklift would struggle to gain access to.

Do you need a forklift or a pallet truck?

Both machines have their benefits, although for those with smaller premises who are also on somewhat of a tight budget should consider implementing a manual pallet truck as opposed to a forklift, simply due to their lower initial cost.

For warehouse owners with a larger amount of money to spend on material handling equipment, then a forklift would be an ideal solution. Forklifts are also beneficial for those who own a premises with a considerable amount of space available or for those with tall warehouse racking, spanning up to the ceiling.

Regardless of the equipment you choose, you’ll be sure to improve the efficiency and productivity throughout your business, ensuring operations run as smoothly and as effectively as possible, all with the implementation of the most ideal material handling machines.

If you would like more information about the pallet trucks and forklifts we have available to purchase, or if you wish to hire a forklift or rent warehouse equipment, then get in touch with a member of our professional, knowledgeable team today – we’re always happy to hear from you.