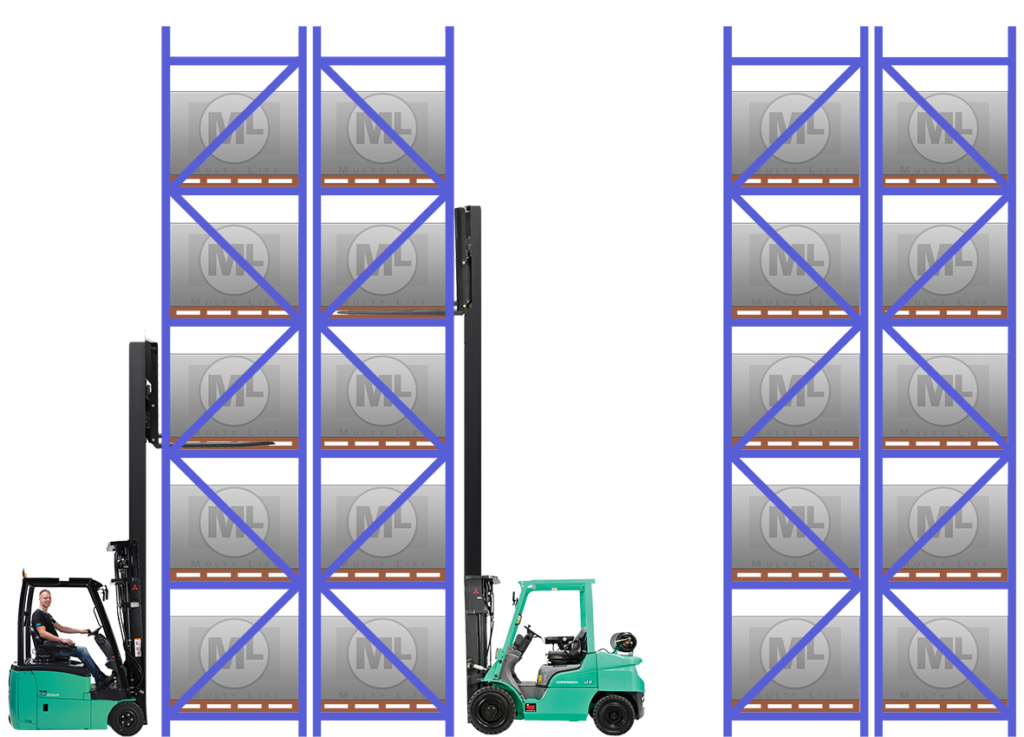

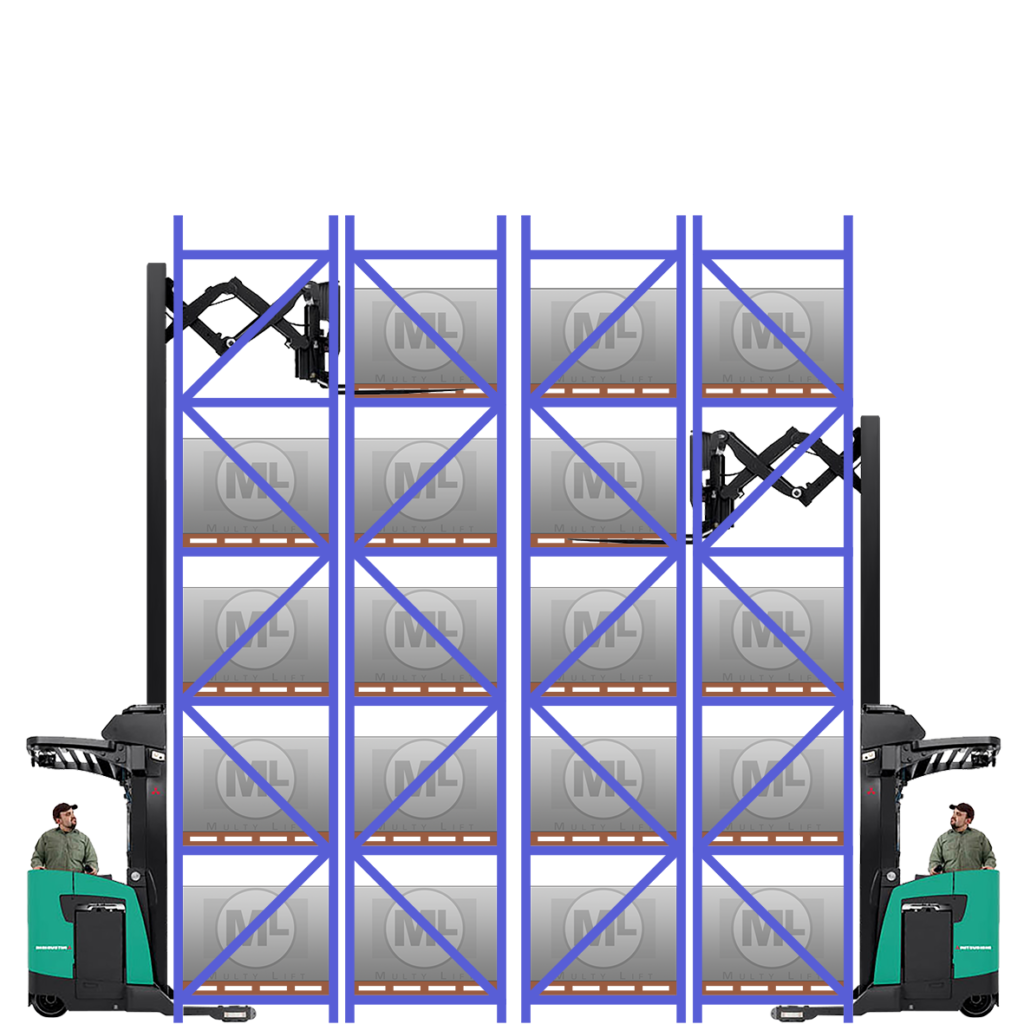

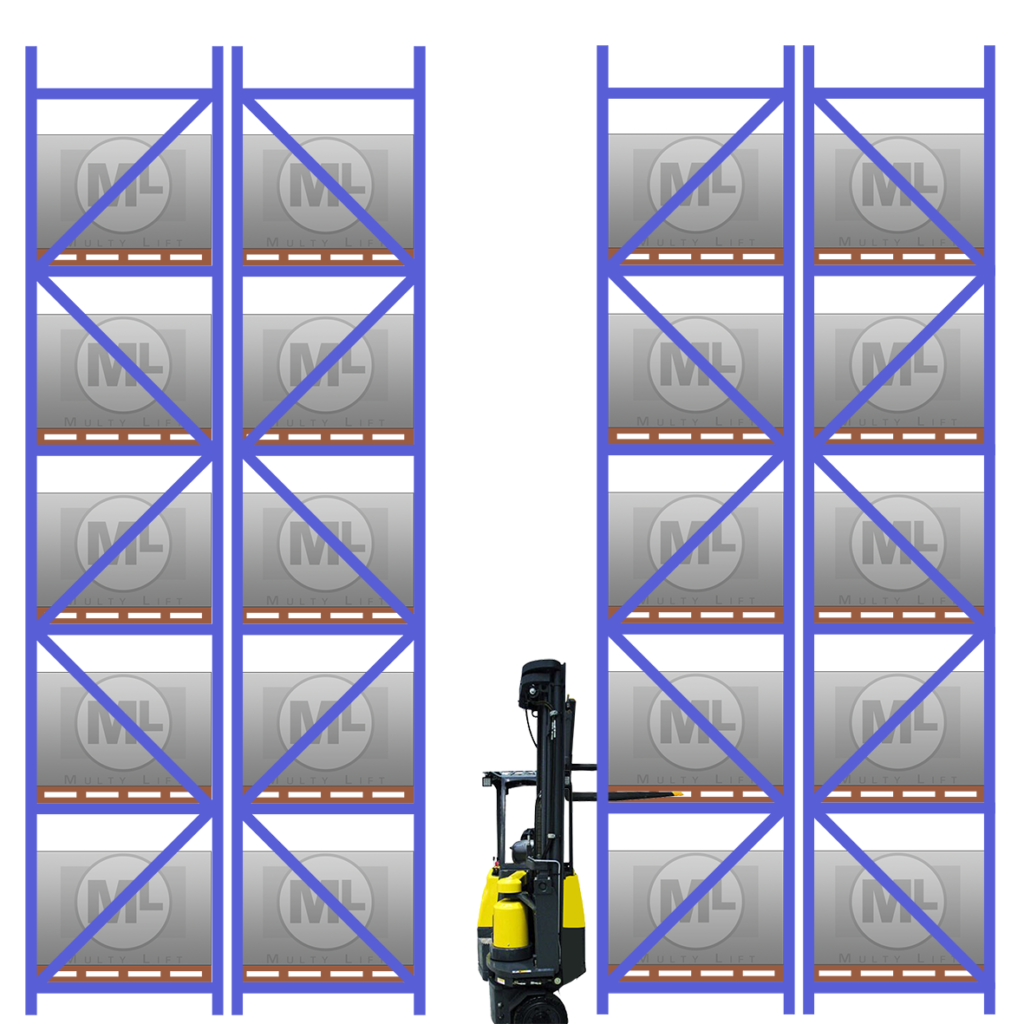

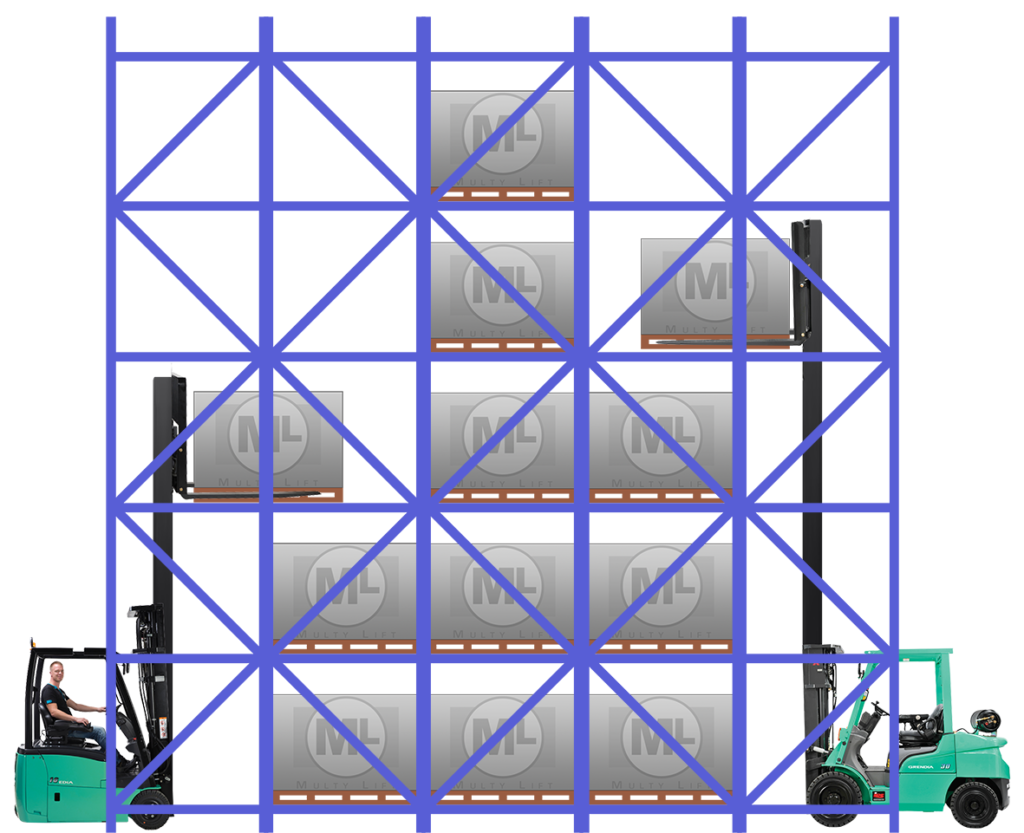

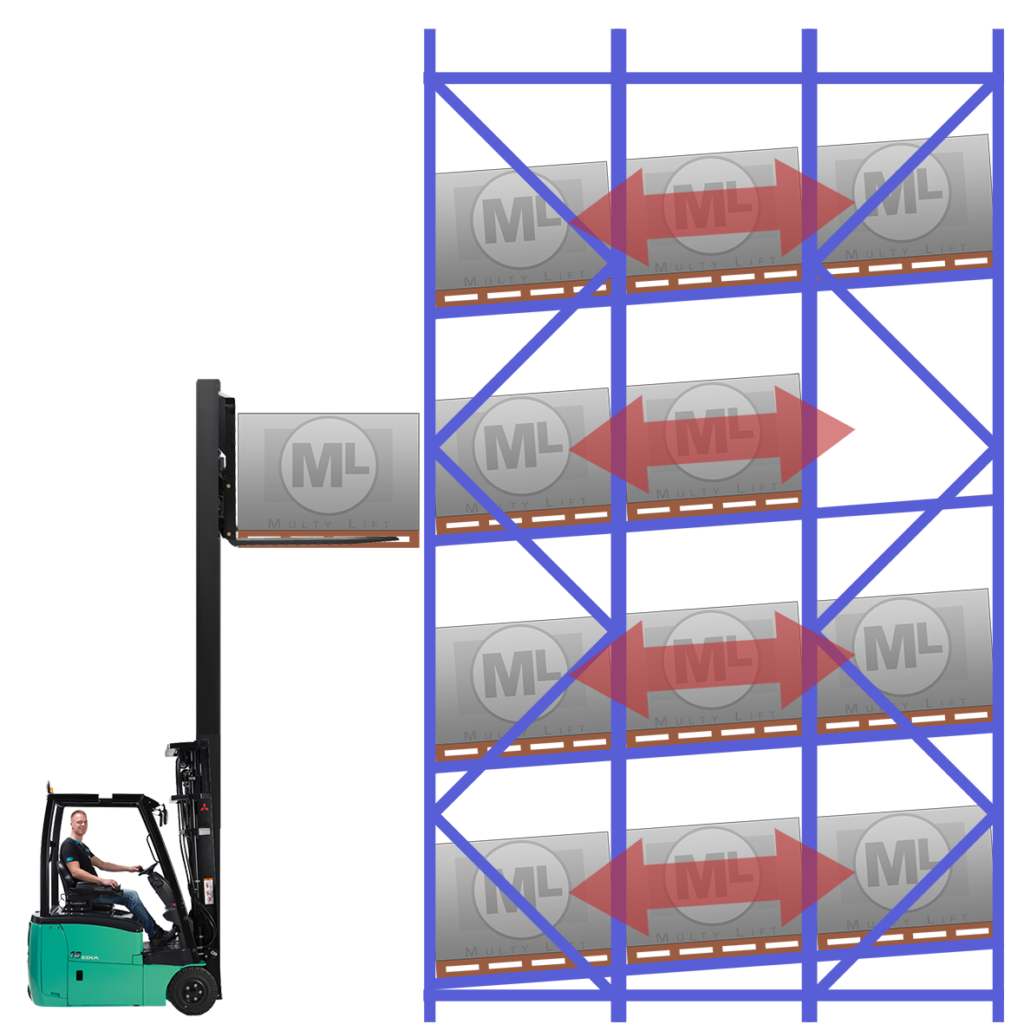

Cantilever Racking is suitable for both indoor and outdoor use, for long or wide loads which don’t fit on regular pallets. This type of racking supports and stores the load safely with the ability to adapt to any change in loads. With the ability to store the load lengthways with support arms, this allows for easy storage and access by forklift truck. Timber, pipes, scrap vehicles and worktops are just a few of the many products which can benefit from being stored on Cantilever Racking. Depending on your requirements and the access needed to each load, this method of storage can even be mobilised on embedded rails and manoeuvred with a remote control or control panel. This can further optimise the space available by having only one aisle open at a time and all the others closed and compact whilst still being easily accessible. At Multy Lift we can provide the correct forklift trucks to manoeuvre your load safely and efficiently. You will have the ability to lift a wide range of weights and sizes of load as well as being able to work both inside and outside to reduce costs of requiring multiple trucks and in turn increase productivity within your business.